Project Description

PROJECT: “BUNKER BREEZE” (5000 m³ LNG-ready Bunkering Tanker)

Structure and outfitting detail engineering

Foran 3D model

Fabrication and workshop drawings

- LOA: 86.07 m

- LPP: 81.68 m

- B: 17.00 m

- D: 7.55 m

- T: 5.60 m

- Crew: 8 p

- Speed: 10 knots

- Power: 2 x 1260 kW

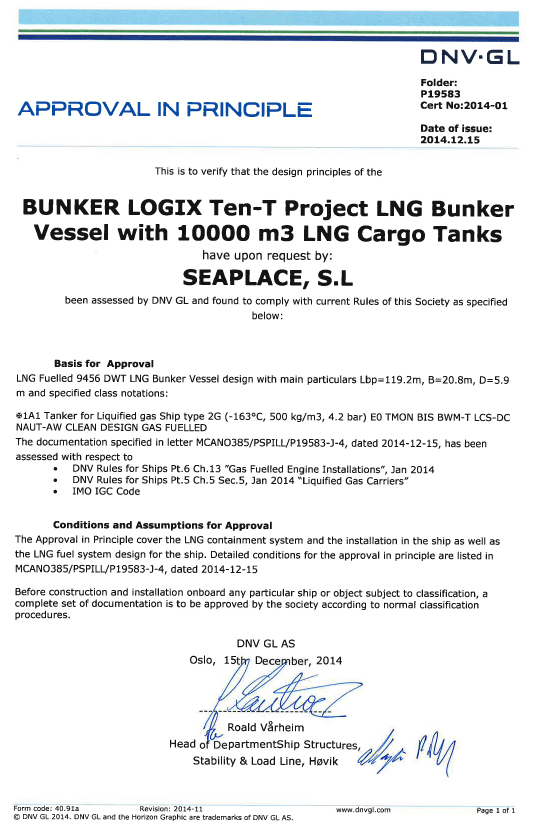

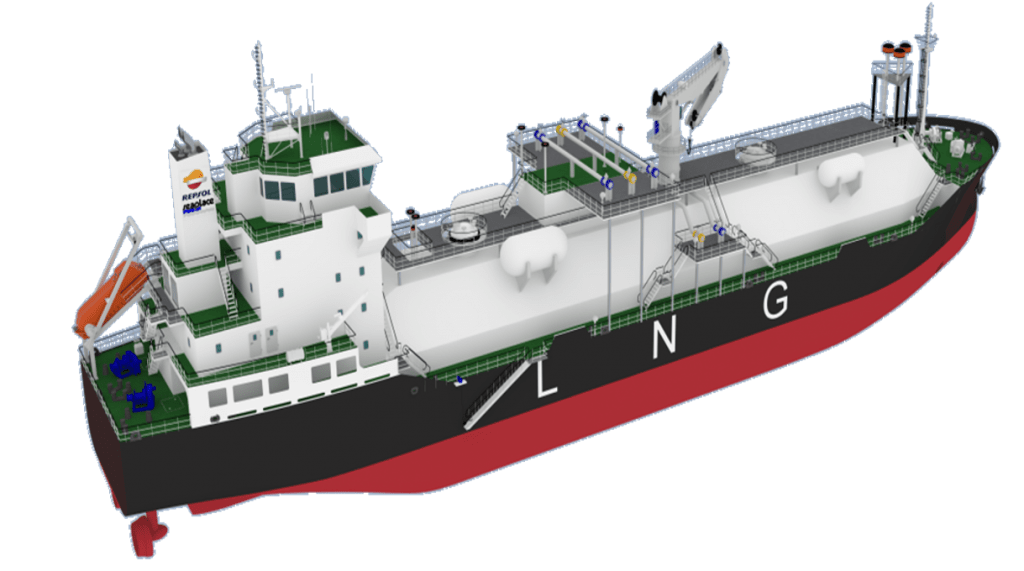

PROJECT: LNG Carrier “Small-Scale” – 10.000 m³

Basic Engineering Design of a LNG gas carrier of 10.000 m³ Small Scale. Gas fuelled

- Dimensioning

- LNG tanks selection and arrangement

- LNG tank sizing and scantling

- General Arrangement

- Structural design

- Propulsion Design

- Main System Design

- LNG bunkering system design

- NG fuel supply design

- LNG loading and discharge

- Safety

- Operational philosophy

- Risk assessment HAZID/HAZOP

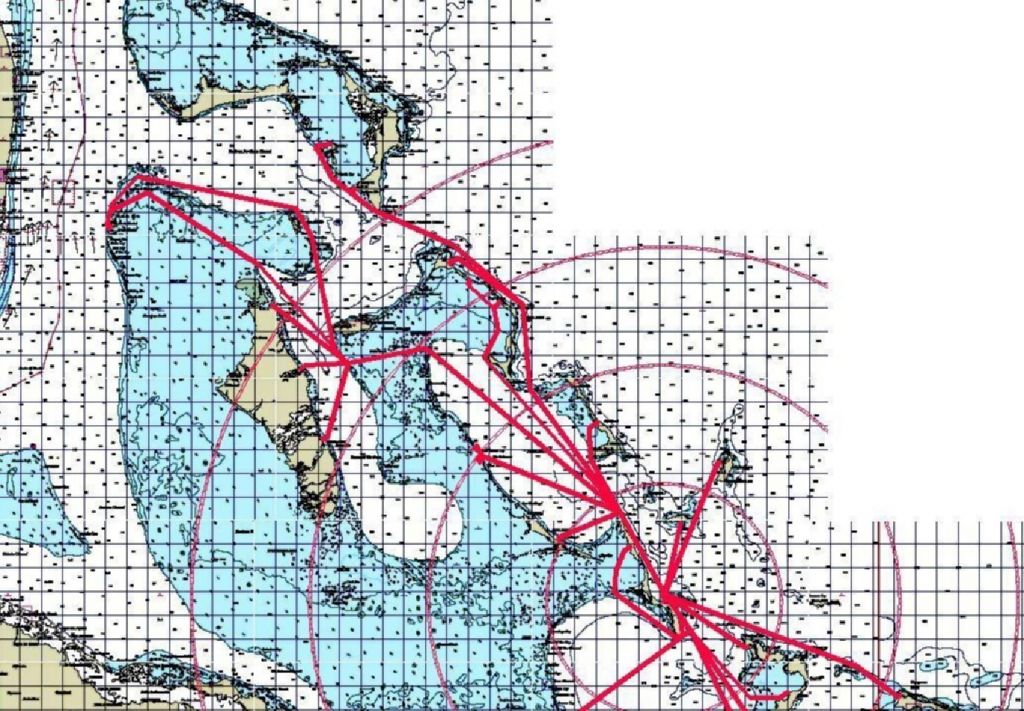

- Terminals Compatibility Analysis (Shore to Ship)

- LOA: 122.90 m

- Beam: 20.80 m

- Design Draft: 5.40 m

- Service Speed: 14 kn

Class Notation:

+1A1 Tanker for Liquefied Gas (-163ºC, 0.5 t/m³, 4.2barg), Ship Type 2G, E0, T-MON, BIS, BWM-T, LCS,DC, NAUT-AW, Clean Design, Gas Fuelled

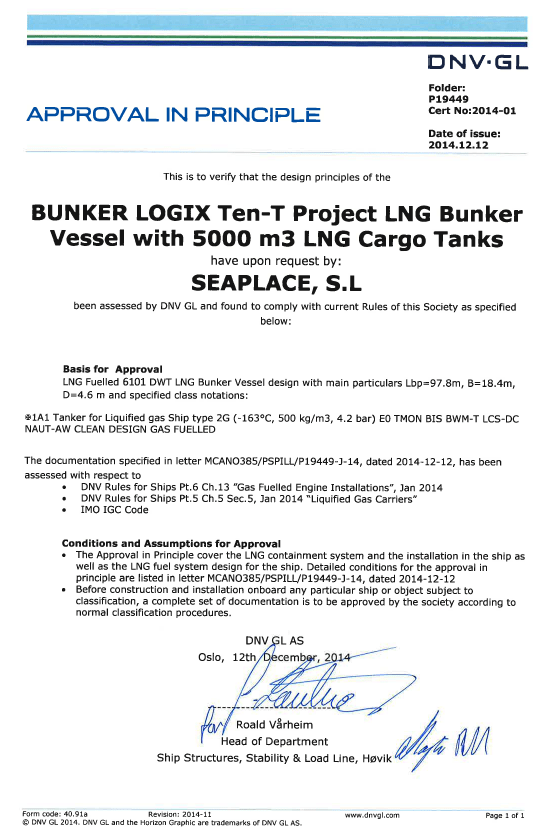

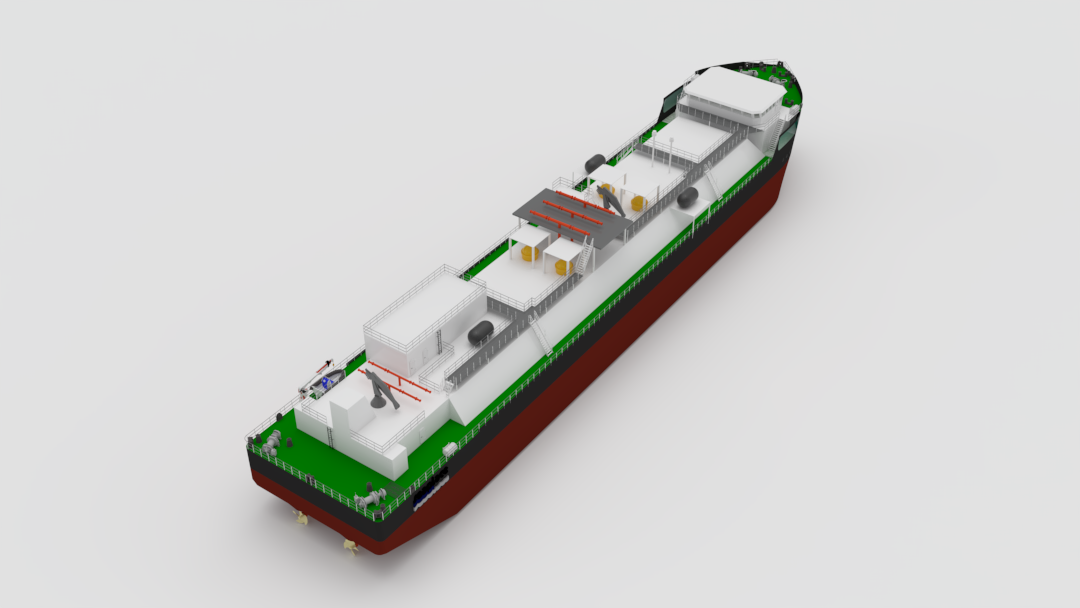

PROJECT: LNG Bunkering Vessel – 5.000 m³

Basic Engineering Design of a LNG Bunker vessel of 5.000 m³. Gas fuelled

- Dimensioning

- LNG tanks selection and arrangement

- LNG tank sizing and scantling

- General Arrangement

- Structural design

- Propulsion Design

- Main System Design

- LNG bunkering system design

- NG fuel supply design

- LNG loading and discharge

- Safety

- Operational philosophy

- Risk assessment HAZID/HAZOP

- Ships Compatibility Analysis (Ship to Ship)

- LOA: 100.47 m

- Beam: 18.40 m

- Design Draft: 4.60 m

- Service Speed: 12 kn

Class Notation:

+1A1 Tanker for Liquefied Gas (-163ºC, 0.5 t/m³, 4.2barg), Ship Type 2G, E0, T-MON, BIS, BWM-T, LCS,DC, NAUT-AW, Clean Design, Gas Fuelled

PROJECT: LNG Bunkering Barge – 5.000 m³

Conceptual Engineering design of a modern LNG Bunker Barge, fitted for transportation of LNG in IMO categorised bilobed type C tanks of approximately 2.500m3 each.

The barge is intended to operate in harbour waters. The barge is specifically designed for:

- Load LNG at standard LNG terminal scale jetty

- Safely bunker cruise liners with overhanging lifeboats

- Safely manoeuvre/ navigate within main operating area to any anchorage area (outside port limits) as needed and without tug support

- Bunkering of membrane and type C LNG tanks.

- LNG tanks cooldown.

- Cooling down of LNG lines of own barge and receiving vessel

- LNG tanks warm up.

- Inerting of: cargo tanks of other vessels; barge’s own LNG tanks; piping and equipment of own barge and receiving vessel

- Gassing up of cargo tanks of other vessels

- LOA: 94.50 m

- LPP: 91.35 m

- Beam: 17.00 m

- Design Draft: 5.50 m

- Service Speed: 8.5 kn

- Class Notation: +1A1, +Liquid Gas (-163ºC, 0.5t/m3, 4barg), Ship type 2G, Gas Fuelled, IWS

PROJECT: Double-ended LNG Bunkering Vessel – 7.500 m³

Conceptual Engineering design of a double ended LNG bunkering vessel 7.500 m³

- Dimensioning

- LNG tank selection and arrangement

- General Arrangement

- Structural definition

- Propulsion definition

Main Particulars

- LOA: 109 m

- Beam: 20.00 m

- Design Draft: 5.30 m

- Cargo tanks: 2 x Type C x 3750m3

- Accomodation: 14 POB

- Power: 3x 1330kWe

Class Notation:

+1A1, LNG bunkering ship (tank type C, -163ºC, 0,50 t/m3, 4,2 bar g), Enviro +, VRS, DFD, HAB +, DPS1

PROJECT: LNG Bunkering Vessel – 7.500 m³

Conceptual Engineering design of a LNG bunker vessel 7.500 m³

- Dimensioning

- LNG tank selection and arrangement

- General Arrangement

- Stability Analysis

- Structural definition

- Propulsion definition

- LNG bunkering system analysis

- LOA: 108.92 m

- Beam: 20.00 m

- Design Draft: 5.30 m

- Service Speed: 12.00 kn

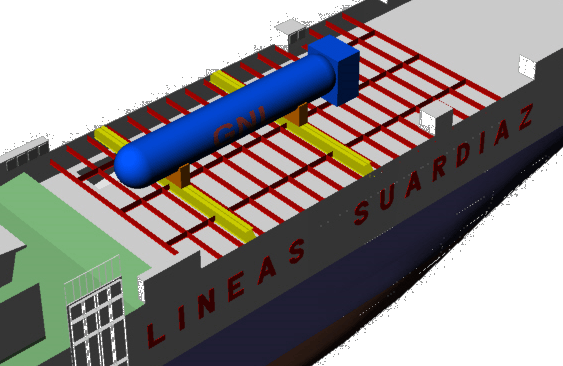

PROJECT: Multi-product bunkering barge HFO/GO/LNG(1.000 m³)

Concept Engineering and Basic Engineering for the retrofitting of the Boluda’s bunker fuel barge to LNG Bunkering. Gas fuelled

- LNG capacity Analysis. LNG Bunker Optimization

- LNG tanks arrangement Design

- Stability and Visibility Design

- Structural Design

- LNG Bunkering Design

- NG fuel supply Design

- Vessel main systems retrofitting Design

- LOA: 73.50 m

- Beam: 16.25 m

- Design Draft: 5.40 m

- Service Speed: 12 kn

The Project development is part of the European

GAINN4MOS project

Class Notation:

I Hull, Mach, Oil Tanker ESP / Flash point above 60, unrestricted navigation, AUT-UMS, LNG Bunkering Ship, Gas Fuelled

PROJECT: LNG Bunkering Vessel – 5.000 m³

Conceptual Engineering design of a LNG bunker vessel 5.000 m³

- Dimensioning

- LNG tank selection and arrangement

- General Arrangement

- Stability Analysis

- Structural definition

- Propulsion definition

- LNG bunkering system analysis

- Safety

- LOA: 103.70 m

- LPP: 97.10 m

- Beam: 16.20 m

- Design Draft: 4.80 m

- Service Speed: 14 kn

PROJECT: LNG Bunkering Vessel – 6.500 m³

Conceptual Engineering design of a LNG bunker vessel 6.500 m³

- Dimensioning

- LNG tank selection and arrangement

- General Arrangement

- Stability Analysis

- Structural definition

- Propulsion definition

- LNG bunkering system analysis

- Safety

- LOA: 100.5 m

- Beam: 18.90 m

- Design Draft: 4.60 m

- LNG Cargo: 2x3250m3

- LNG buffer: 2x40m3

- Accommodation: 14

- Gas-electric propulsion

PROJECT: Gas fuelled TUG

Concept and Basic Engineering Design of the first port operation and escort tug <500 GT Gas Fuelled

- Tug Dimensioning

- General Arrangement

- LNG tank sizing and Arrangement

- Structural Design

- Propulsion Design

- Main System Design

- NG supply design

- Safety

- Hazardous Areas

- LOA: 29.50 m

- Beam: 12.80 m

- Design Draft: 3.50 m

- GT: 499

- LNG tank: 70 m³

The Project development is part of the European

Core LNGas hive project

Class Notation:

I+HULL, + MACH, Escort Tug, FIFI1 Water Spray, AUT-UMS, COMF NOISE1, GAS FUEL, INWATER SURVEY

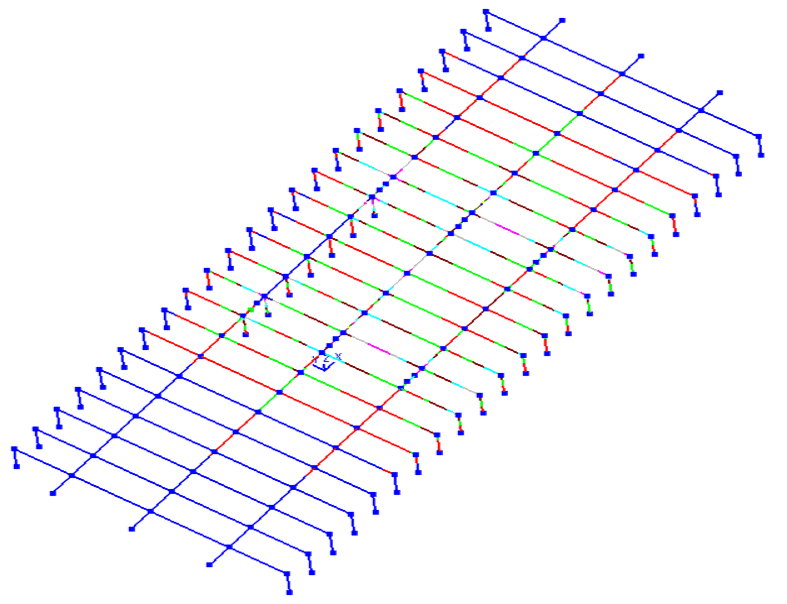

PROJECT: RoRo Retrofitting to Gas Fuelled

Conceptual Engineering Retrofitting of a RoRo to Gas fuelled (HFO/LNG)

- RoRo Operational Analysis

- LNG tanks sizing and arrangement on board

- Stability and visibility analysis

- Structural Analysis

- NG fuel supply Analysis

- LNG Bunkering Analysis

- Vessel main systems retrofitting Analysis

- Safety Analysis